Selected Projects

2023

-

-

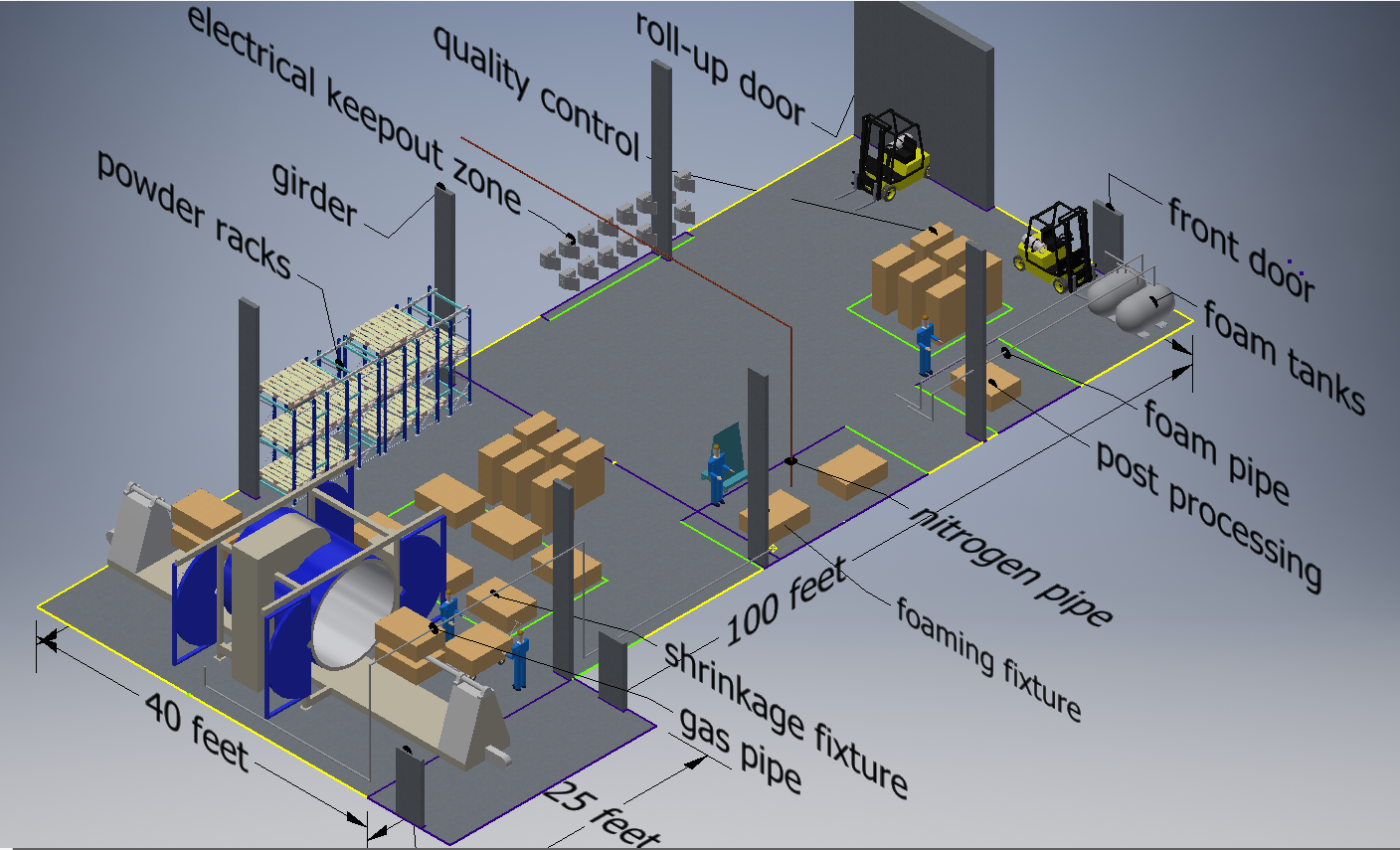

New Production Line Project Management

ABSTRACT

SUB PROJECTSI was in charge of making a new production line, click on the sub projects to see each part of it.

Automatic Mold Lift MachineBuilding Extension-

-

Automatic Mold Lift Machine

ABSTRACT

An automatic mold lift machine is designed to handle and transport heavy molds used in manufacturing, improving efficiency and reducing manual labor. It operates with precision controls to align and place molds into production machinery, such as injection molding or press machines, minimizing downtime. This machine is a crucial component in automated manufacturing lines, where mold changes are frequent and must be executed quickly to maintain production flow.

Rollout Platform-

-

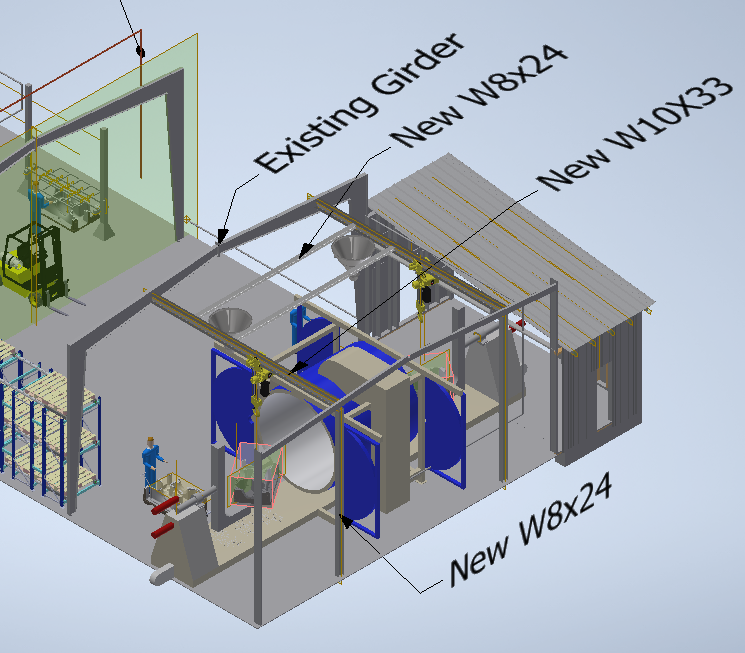

Building Extension

ABSTRACT

This robust structure serves as the backbone for supporting heavy industrial equipment, potentially for material handling or maintenance access in large facilities. Engineered to withstand substantial loads, the framework is constructed with high-grade steel, ensuring stability and safety at significant heights. Its design likely incorporates modularity and scalability, allowing for future expansions or adaptations to meet evolving industrial demands.

Rotomolding Machine-

-

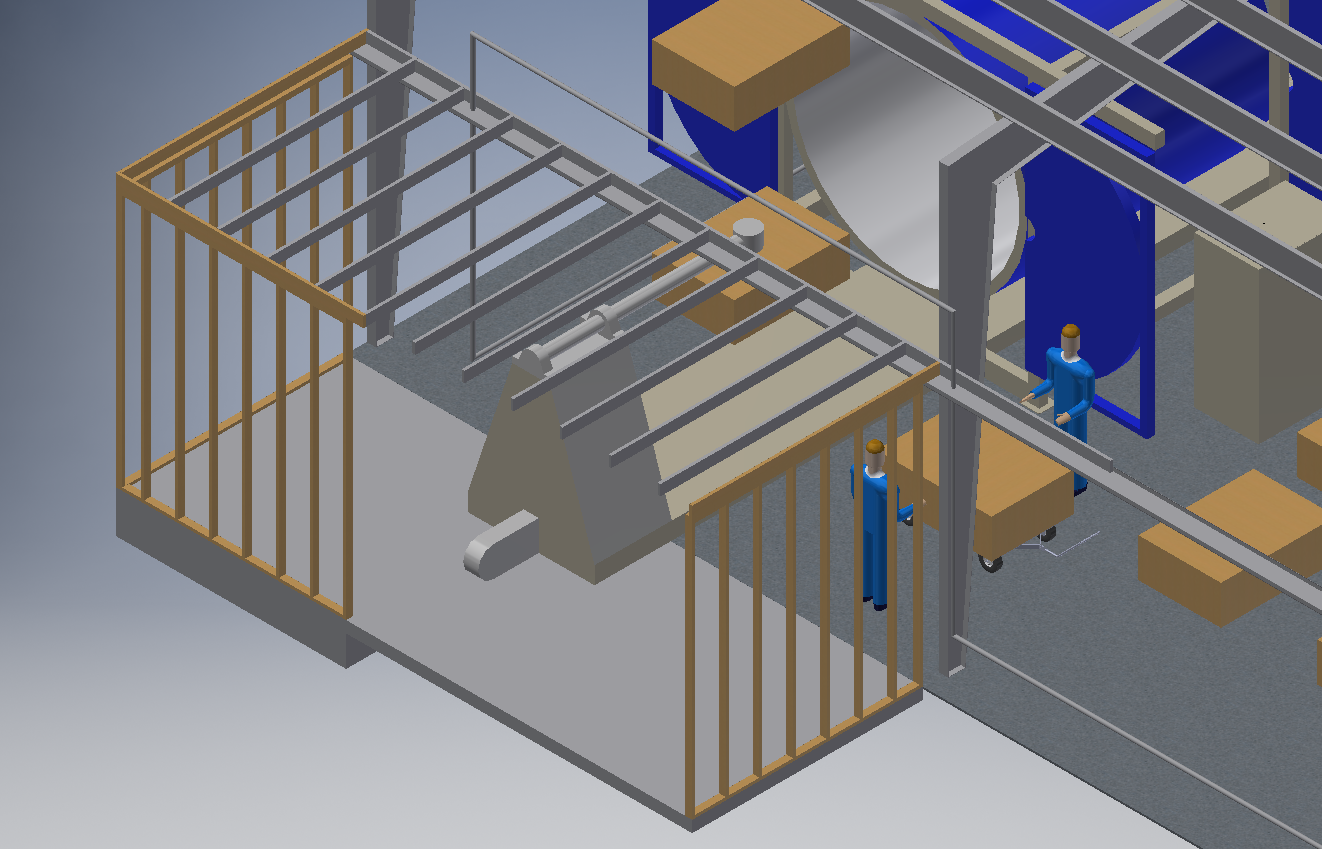

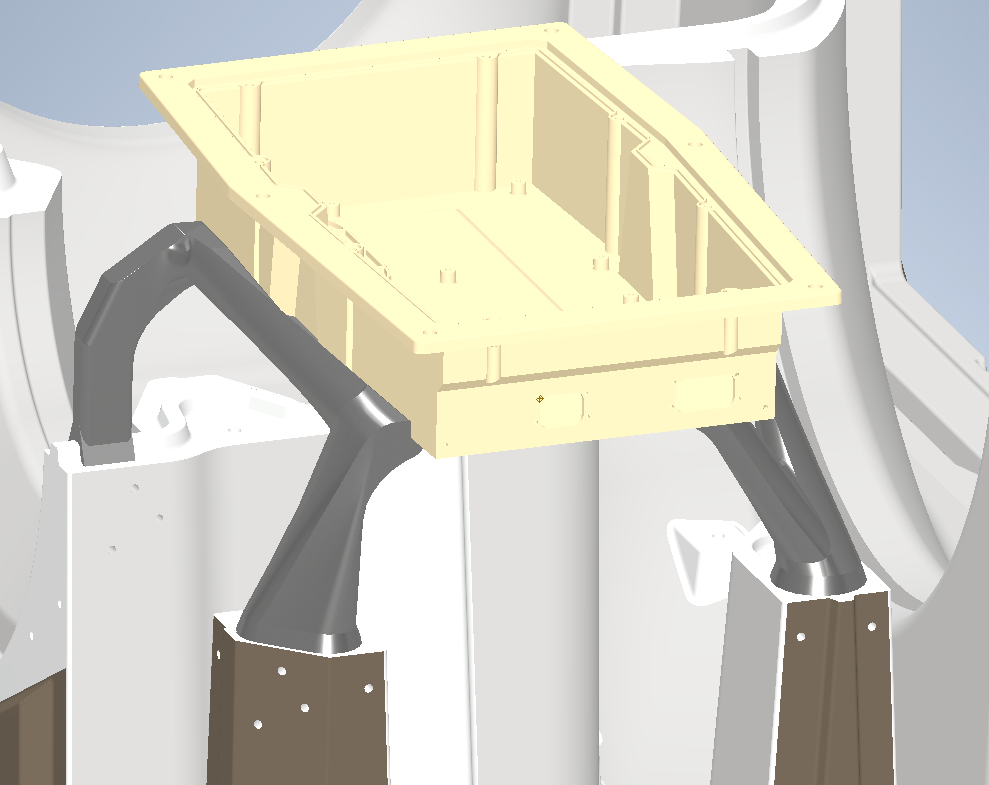

Rollout Platform

ABSTRACT

This platform is likely an adjustable work station that can be extended or retracted to provide operators with access to various heights and angles in a manufacturing or maintenance environment. Its design focuses on ergonomics and safety, featuring guardrails and stabilization mechanisms to protect workers when they are performing tasks at elevated positions. The extendable nature of the platform allows for a compact footprint when not in use, maximizing space efficiency within the facility.

Steel Framework-

-

Rotomolding Machine

ABSTRACT

This robust structure serves as the backbone for supporting heavy industrial equipment, potentially for material handling or maintenance access in large facilities. Engineered to withstand substantial loads, the framework is constructed with high-grade steel, ensuring stability and safety at significant heights. Its design likely incorporates modularity and scalability, allowing for future expansions or adaptations to meet evolving industrial demands.

-

-

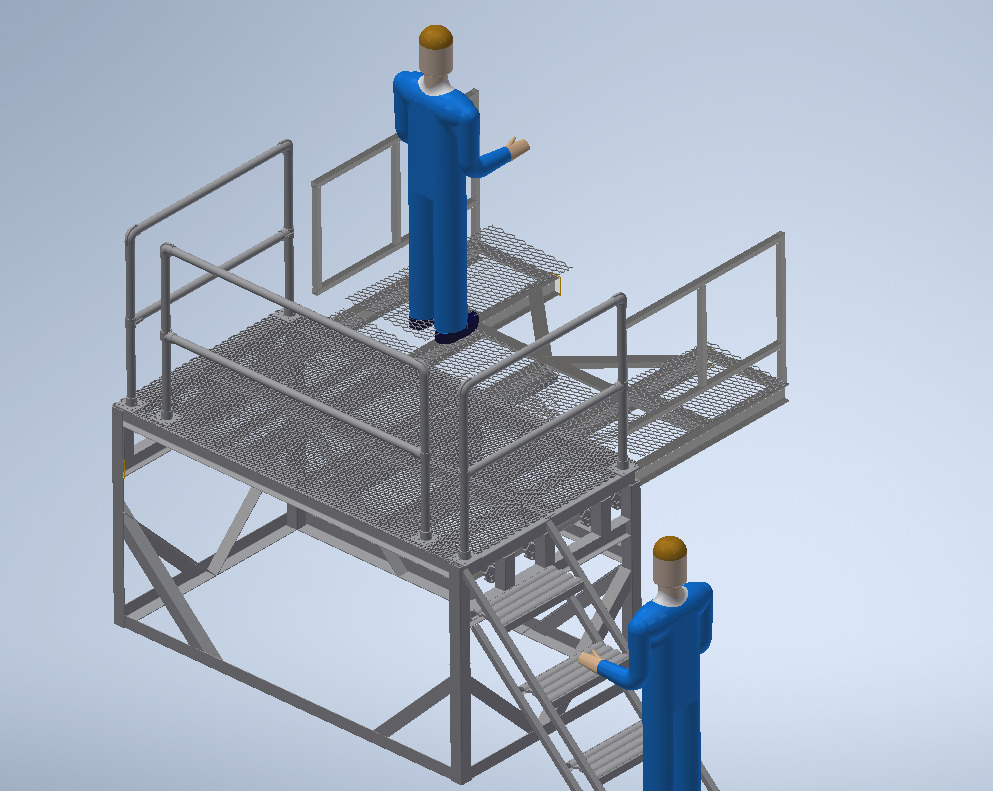

20’ High Steel Framework

ABSTRACT

This robust structure serves as the backbone for supporting heavy industrial equipment, potentially for material handling or maintenance access in large facilities. Engineered to withstand substantial loads, the framework is constructed with high-grade steel, ensuring stability and safety at significant heights. Its design likely incorporates modularity and scalability, allowing for future expansions or adaptations to meet evolving industrial demands.

-

-

-

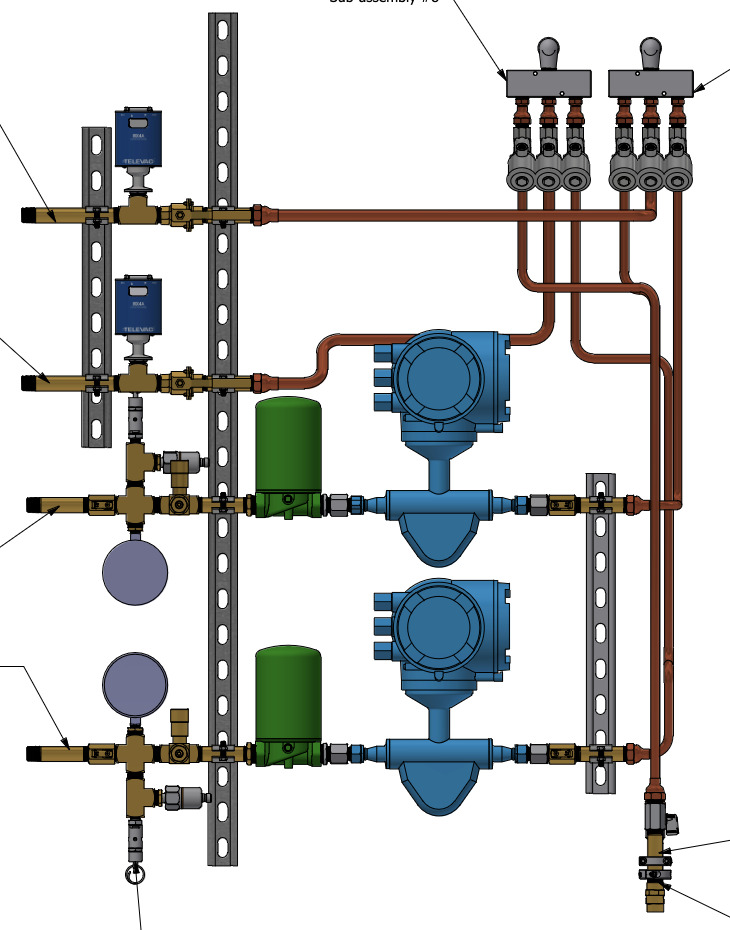

Refrigerent Fill System

ABSTRACT

This is a machine that vacuums and charges a network of pipes with refrigerant. The operator simply plugs in a single hose into a desired unit, and an automated process takes care of the rest.

-

-

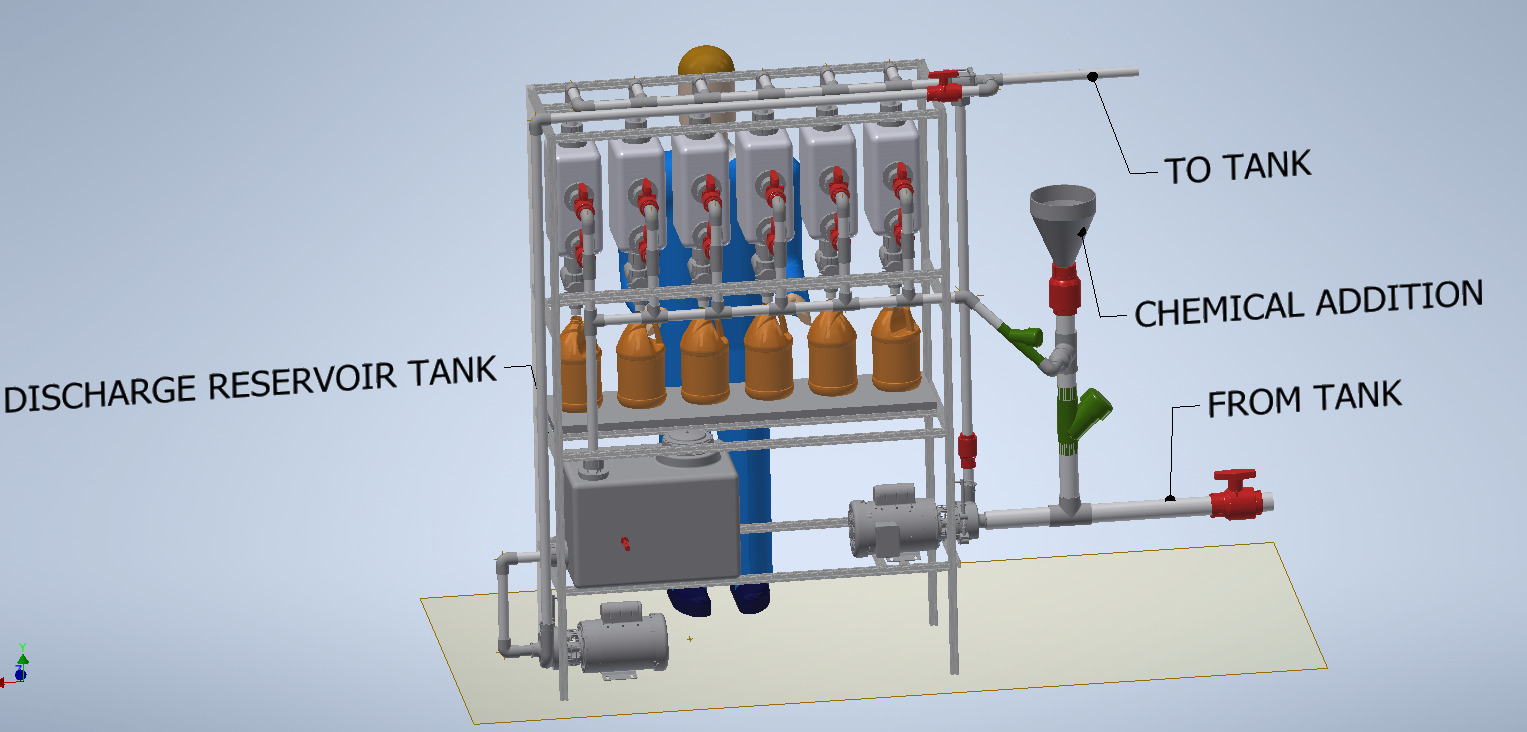

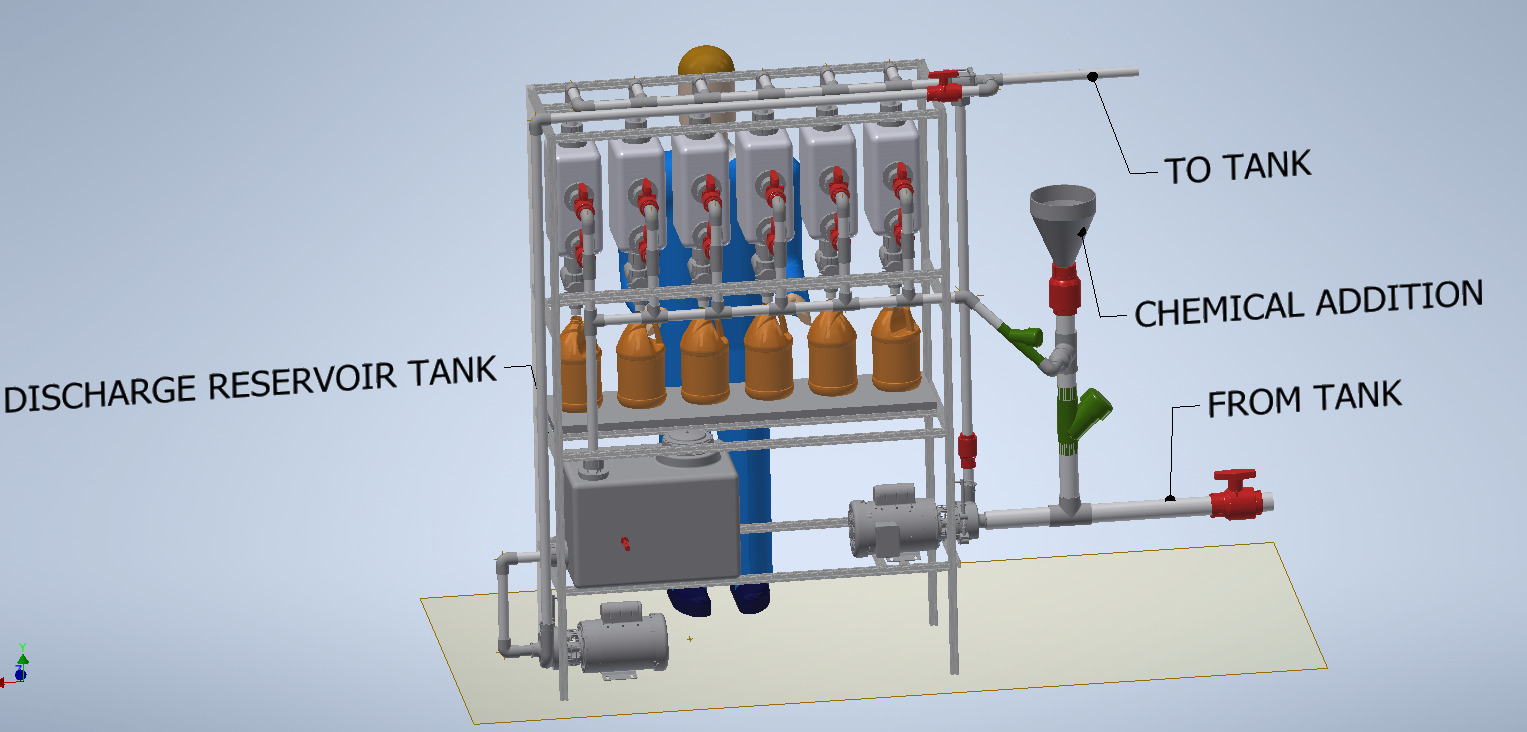

High Volume Production Bottle Fill System

ABSTRACT

Designed for speed and precision, this system rapidly fills bottles with liquids, handling thousands of units per hour to meet high consumer demand. It integrates advanced sensors and control systems to ensure consistent fill levels and reduce spillage, contributing to cost efficiency and product quality. The fill system might also feature quick changeover capabilities to accommodate different bottle sizes and shapes, enhancing its versatility in a production setting.

-

-

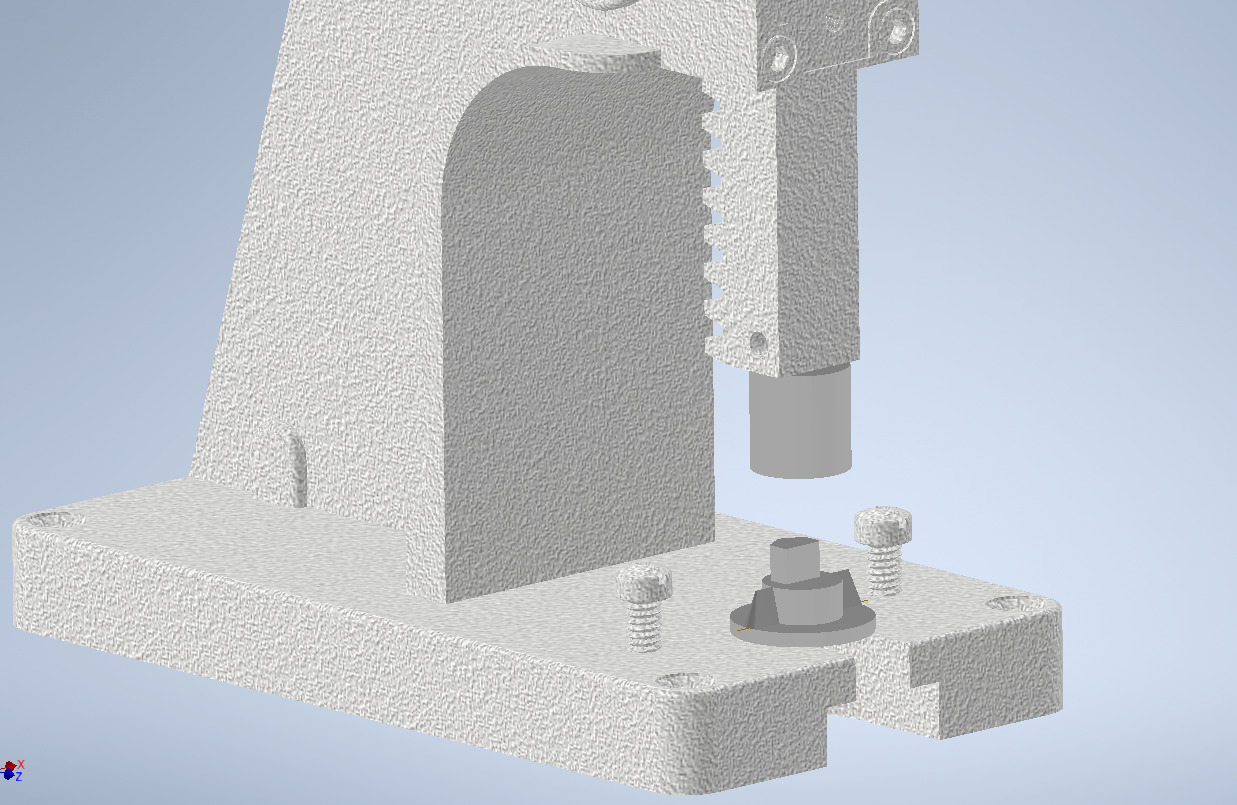

High Force Automated Crimp Tool

ABSTRACT

I designed this tool to replace large, unwieldy manual crimp jaws. The previous tool was not intended for high-volume production and slowed down labor while being inconvenient to use. My air-pressure powered crimp jaws actuate quickly and consistently, dramatically improving throughput on the power cables they crimp.

-

-

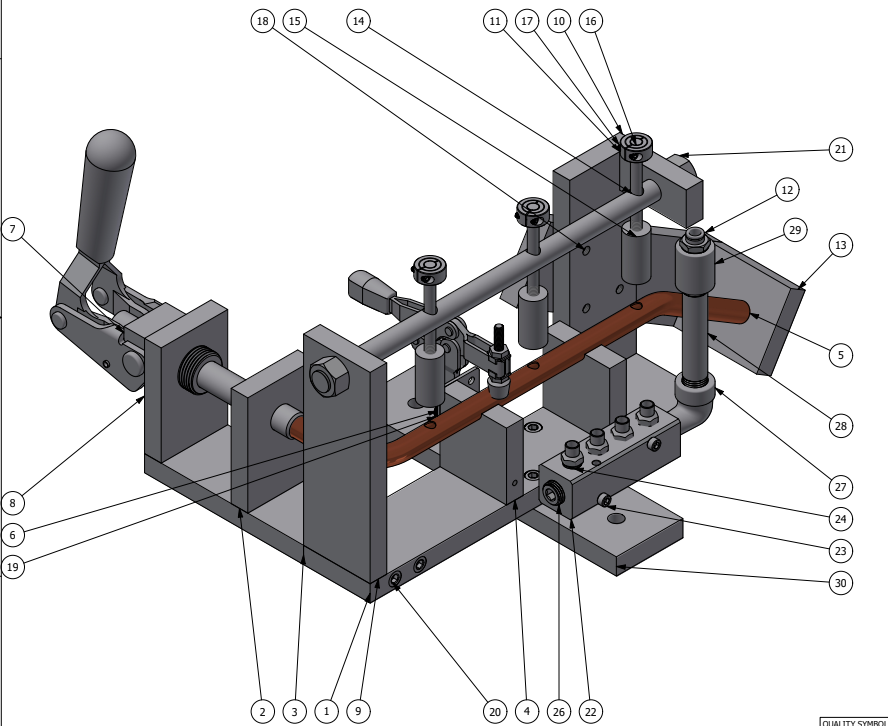

High Volume Production Pipe Fixtures

PDFABSTRACT

These fixtures are specialized clamps or holders designed to keep pipes in place during machining, welding, or assembly in a high-volume production context. They are built to be robust and precise, allowing for rapid setup and changeover to maintain productivity while ensuring consistent product quality. The pipe fixtures may feature modular components to accommodate various pipe diameters and lengths, enhancing their utility across different projects.

-

-

Dangerous Liquid Part Plunger

ABSTRACT

This device is designed to safely insert or remove parts from containers filled with hazardous liquids, preventing exposure and contamination. It likely features chemical-resistant materials and a mechanism that allows for parts to be manipulated without direct contact by the operator. Its use is essential in industries like chemical manufacturing or waste management, where handling dangerous liquids is a routine necessity.

-

-

Failed Part Recovery Tool

ABSTRACT

This tool is tailored for identifying and extracting defective parts from a production line, ensuring that only quality products reach the end consumer. It may incorporate sensors or vision systems to detect anomalies and a mechanical system to remove the faulty items without interrupting the production flow. The recovery tool helps to maintain high standards of quality control and reduces waste by allowing for the possibility of reworking or recycling the failed parts.

-

-

Pressurized Bottle Piercing Machine

ABSTRACT

This machine is specifically engineered to puncture pressurized bottles in a controlled and safe manner, likely for recycling or disposal purposes. It would have robust safety features to contain any potential hazards from the pressurized contents during the piercing process. The system is critical in industries that deal with pressurized canisters, ensuring environmental and worker safety by preventing uncontrolled release of the contents.

-

-

Miscellaneous Fixtures

ABSTRACT

These are custom-designed tools or components created using 3D printing technology to enhance the efficiency and ease of manufacturing processes. By being tailored to specific tasks, they can significantly reduce setup times and improve the ergonomic handling of materials or products on the production floor. The use of 3D printing allows for rapid prototyping and iteration, enabling quick integration of improvements into the production line.

2022

-

-

Formula SAE Racecar

ABSTRACT

This is a high-performance, student-engineered racecar designed for the Formula SAE competition, which challenges students

-

-

Machinist for RPI Research Institute

ABSTRACT

A machinist at the RPI (Rensselaer Polytechnic Institute) Research Institute would be skilled in precision machining techniques, tasked with creating intricate parts and components for various research projects. Utilizing both traditional machining tools and advanced CNC (Computer Numerical Control) equipment, they would fabricate items to exact specifications required for complex scientific investigations. The role is critical for the development of prototypes and custom apparatuses that enable breakthroughs in engineering and scientific research, requiring a high level of technical knowledge and attention to detail.

-

-

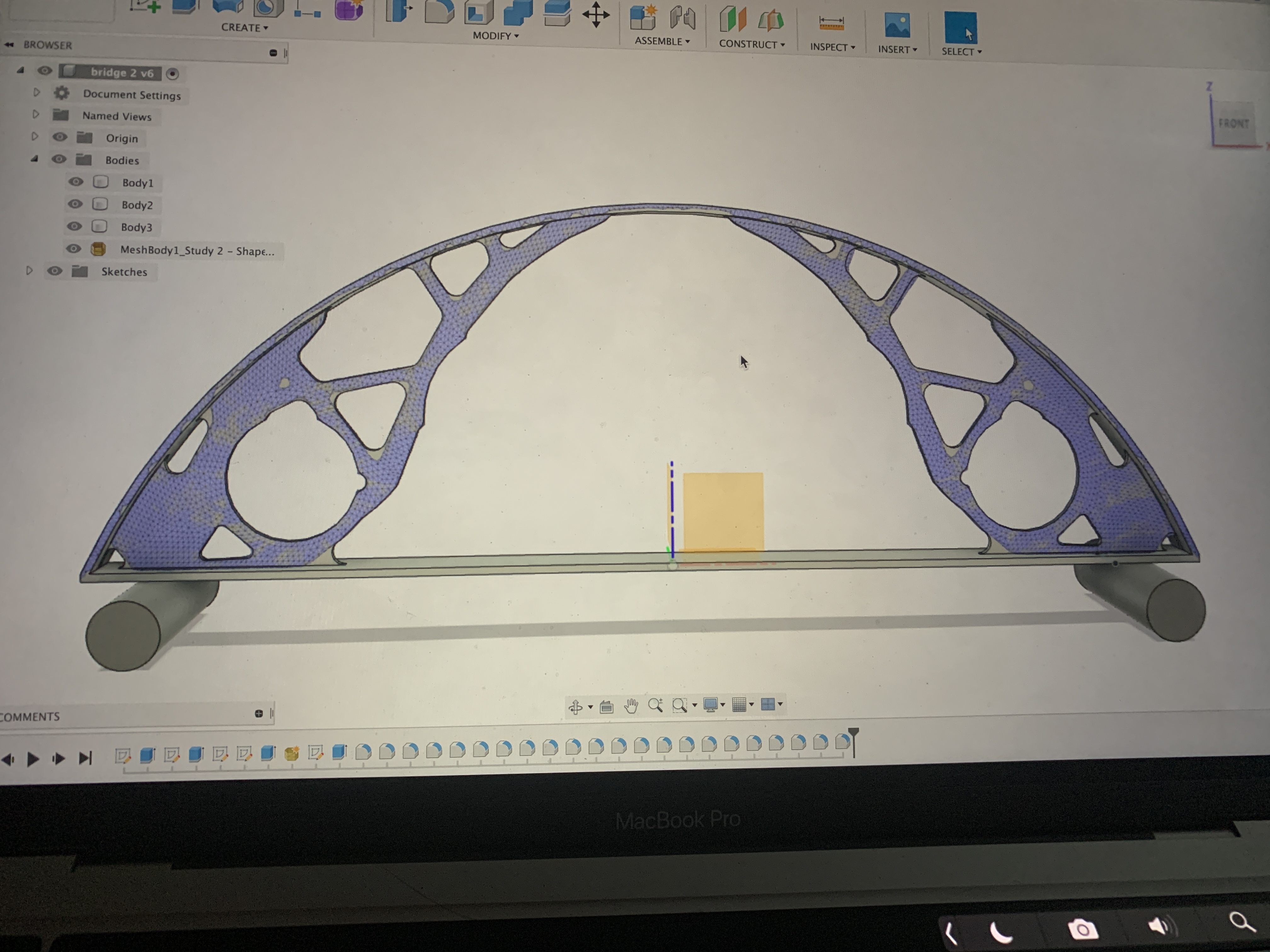

Scaled Model CNC Curved Bridge Design

ABSTRACT

This refers to the use of CNC machinery to create a scaled-down model of a curved bridge, often used in architectural studies or structural engineering simulations. The design process would involve precise programming of the CNC machine to carve the model from suitable materials, replicating the intricate curves and structural elements of the bridge at a reduced size. Such models are crucial for visualizing design concepts and conducting physical stress tests, providing valuable data for the feasibility and safety of the full-sized structure.